Inside the Modern Gum-Making Machine

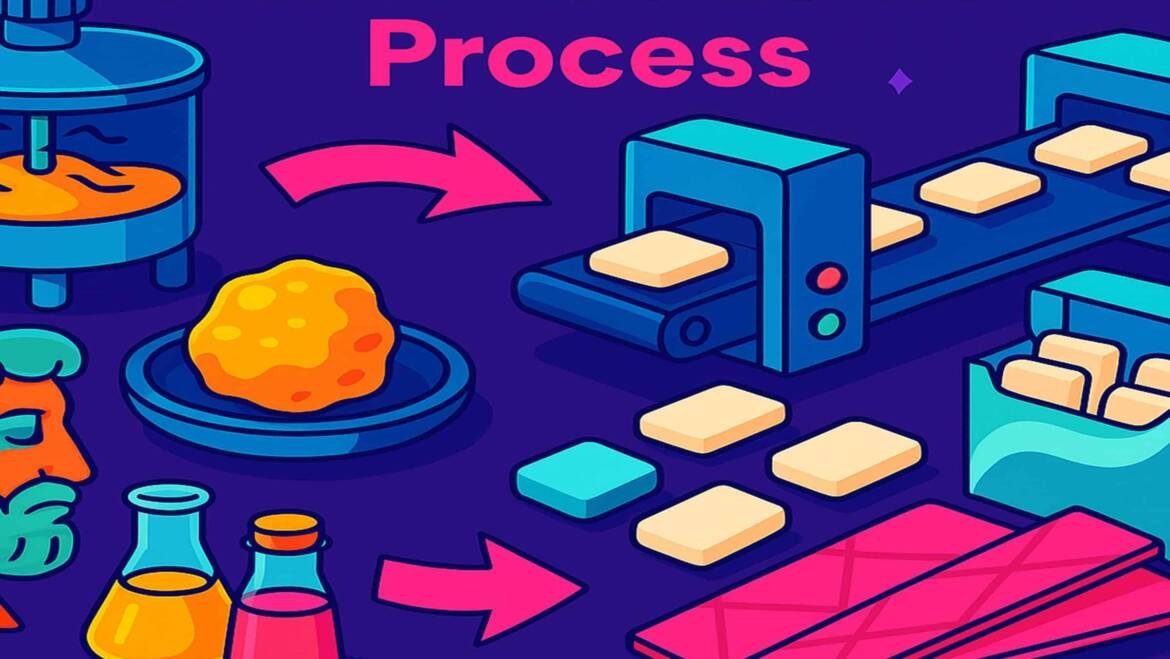

Ever wonder how your favorite gum gets from sticky idea to glossy wrapper? The journey starts with base ingredients—synthetic rubber, waxes, and softeners. These are mixed into a smooth, chewy paste in heated mixers. Next come flavors: mint, fruit, coffee—even spicy surprises.

After mixing, the gum is cooled and kneaded like dough. Machines stretch, flatten, and cut the gum into neat shapes. Each piece is dusted with powder to prevent sticking and boost texture. It’s then wrapped—foil, paper, blister packs—all with sleek branding.

Modern factories use AI for quality control and flavor consistency. Robotic arms package thousands of pieces per minute. Sustainability is key—eco-friendly wrappers and biodegradable bases are trending. Some factories even recycle the heat from machines to reduce energy waste.

The entire process is quick, clean, and ridiculously precise. From industrial steel to neon-colored conveyor belts, it’s gum-tech galore. Brands are adding vitamins, caffeine, and even mood boosters. Gum today is smart, stylish—and definitely beyond basic.

So next time you pop a piece, imagine the futuristic dance of production behind it. It’s chewy, clever, and crafted with tech-powered flair. Modern gum isn’t just made—it’s engineered for delight. 💫

2 Comments

What a joyful website! We loved your little store and are planning on ordering some of the amazing sweets for our kid’s BD party!

The service was fantastic. i appreciate the wonderful job done for me and hope you guys continue to do what you are doing for your customers